DRY ICE DETAILING

What is Dry Ice Detailing?

Dry ice detailing is a cutting-edge cleaning technique that uses dry ice—frozen carbon dioxide (CO₂)—to clean vehicles with precision and care. Unlike traditional methods that rely on water, harsh chemicals, or abrasive scrubbing, dry ice detailing is completely non-abrasive, chemical-free, and eco-friendly.

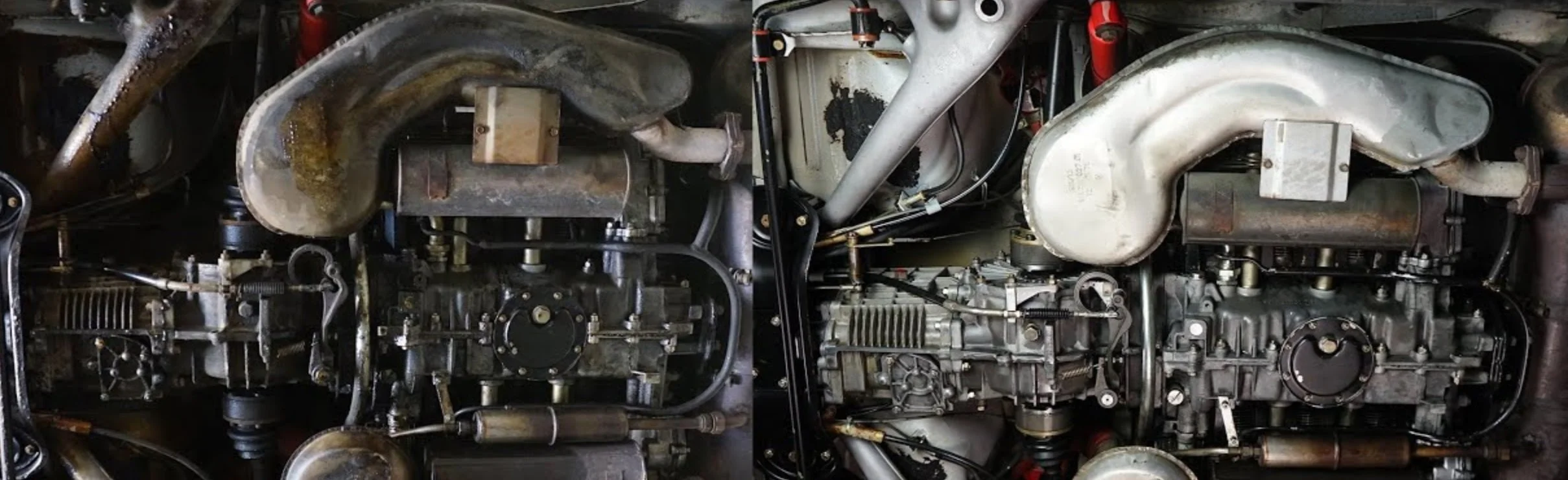

This process is perfect for restoring vehicles, cleaning intricate or sensitive areas, and achieving showroom-quality results without risking damage to the vehicle’s paint, metal, or components.

What is Dry Ice?

Dry ice is the solid form of carbon dioxide, a gas naturally found in the atmosphere. At a temperature of -109.3°F (-78.5°C), CO₂ freezes into a solid. When it warms up, it sublimates—turns directly from solid to gas—without leaving behind any liquid residue.

Dry ice is safe, non-toxic, and widely used in industries ranging from food preservation to cleaning. Its unique properties make it ideal for vehicle detailing, as it cleans effectively while protecting sensitive surfaces.

How is Dry Ice Detailing Done?

The dry ice detailing process is performed using specialized equipment designed to deliver exceptional results. Here’s how it works:

Assessment and Preparation:

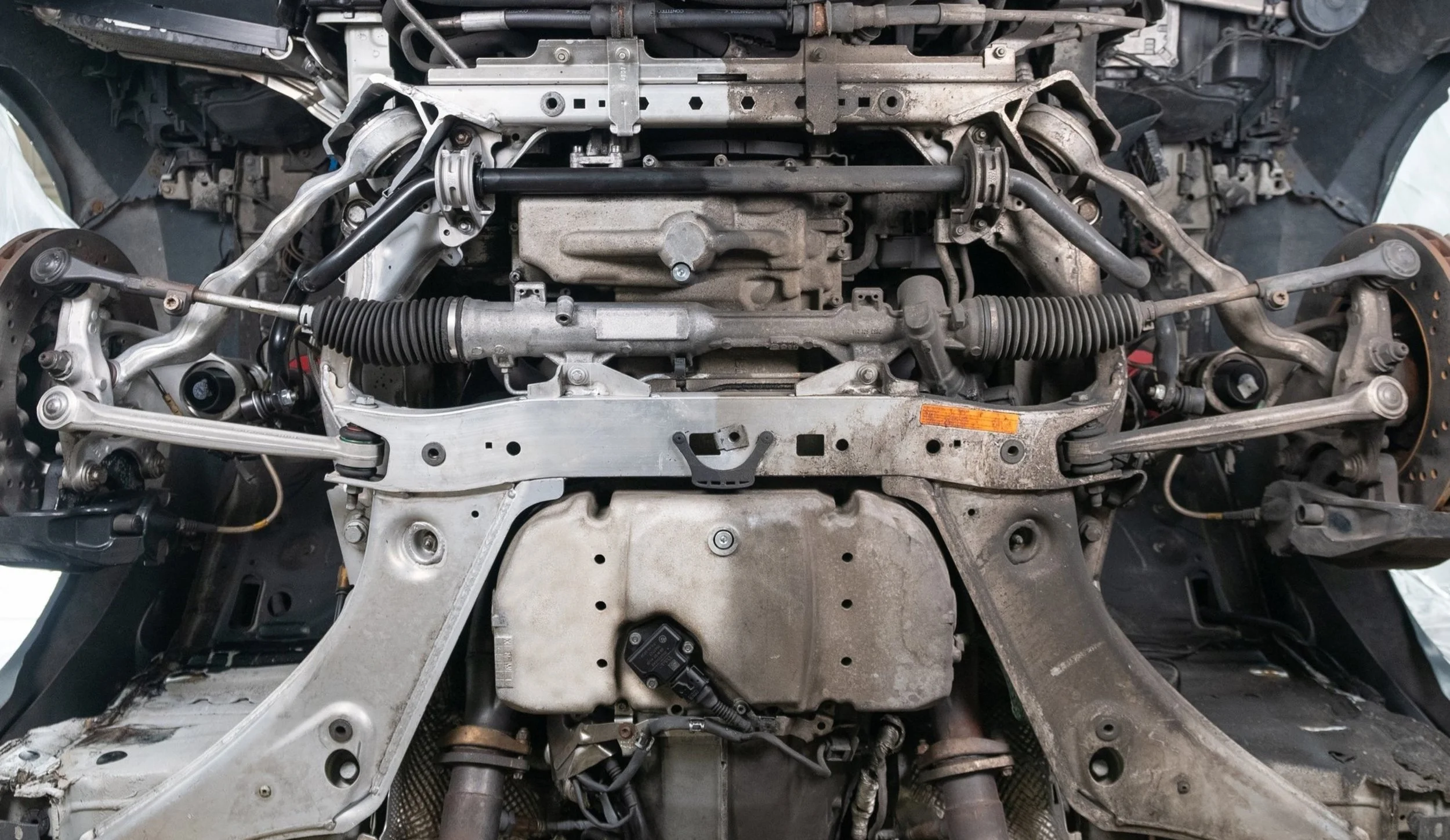

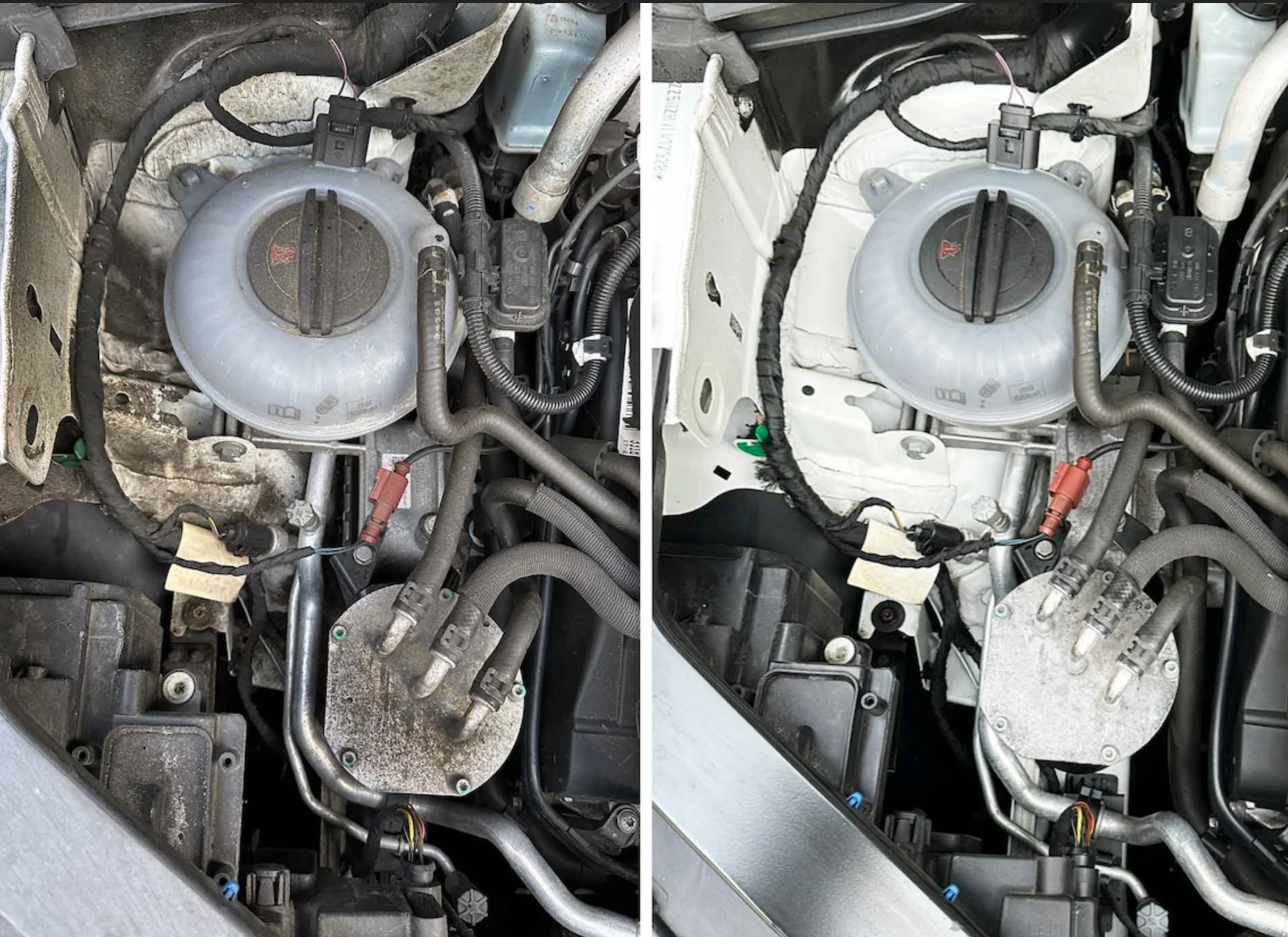

The vehicle is inspected to identify areas requiring attention, such as the engine bay, undercarriage, wheels, or interior components.Application of Dry Ice:

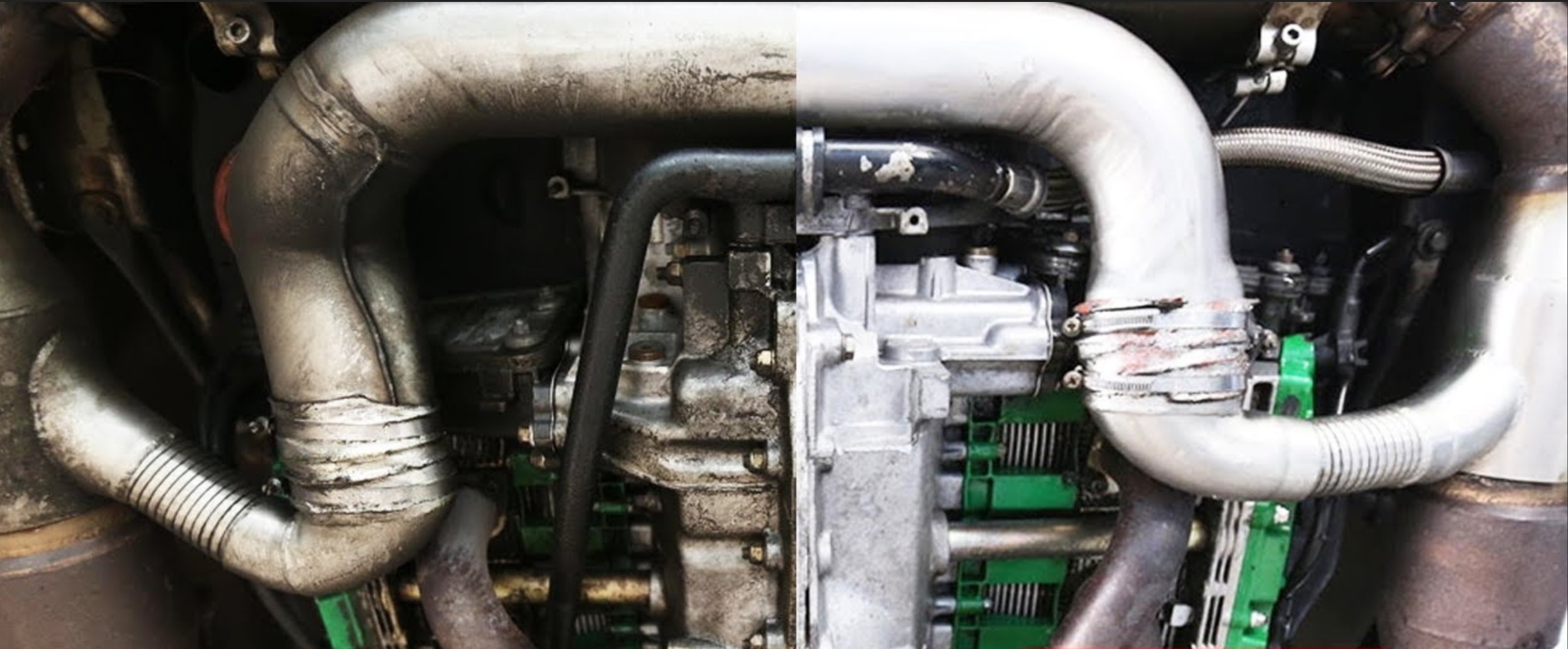

Using a high-pressure machine, dry ice pellets are directed at the surface of the vehicle. Upon impact, the pellets instantly sublimate, creating a small burst of energy that lifts dirt, grease, and contaminants away from the surface.Precision Cleaning:

The process is highly targeted, allowing technicians to clean intricate areas without overspray, water damage, or abrasion.Inspection and Finishing Touches:

Once complete, the vehicle is inspected to ensure every detail is flawless. No drying or rinsing is required because the process is residue-free.

Why Should You Choose Dry Ice Detailing?

Dry ice detailing offers unparalleled advantages over traditional cleaning methods. Here’s why it’s a preferred choice:

Preserves Delicate Surfaces:

Dry ice is gentle and non-abrasive, making it ideal for cleaning sensitive areas like vintage paintwork, modern clear coats, and intricate components.Waterless Cleaning:

With no water involved, there’s no risk of electrical damage or rust formation. This is especially valuable for cleaning engine bays and undercarriages.Eco-Friendly Solution:

Clients who care about the environment appreciate the absence of harmful chemicals and water waste.Recycled CO₂:

The dry ice used in detailing is often a byproduct of industrial CO₂ capture. This means it reuses existing CO₂ rather than releasing new emissions.Versatility: Ideal for engine bays, undercarriages, and interior detailing, where precision and care are paramount.

Restoration Quality:

Dry ice cleaning removes stubborn grime and contaminants from hard-to-reach areas, leaving your car looking like it just rolled off the assembly line.Saves Time and Effort:

Since the process doesn’t require drying or chemical cleanup, your vehicle is ready to go immediately after detailing.